The Benefits of OEM Parts CNC Machining for Your Business

In today's highly competitive business landscape, staying ahead of the curve is essential for sustained success. When it comes to manufacturing and precision engineering, utilizing the right tools and technologies can make all the difference. That's where OEM parts CNC machining comes into play. In this article, we will explore the numerous benefits of OEM parts CNC machining and how it can empower your business in the Home Services, Contractors, and Building Supplies industries.

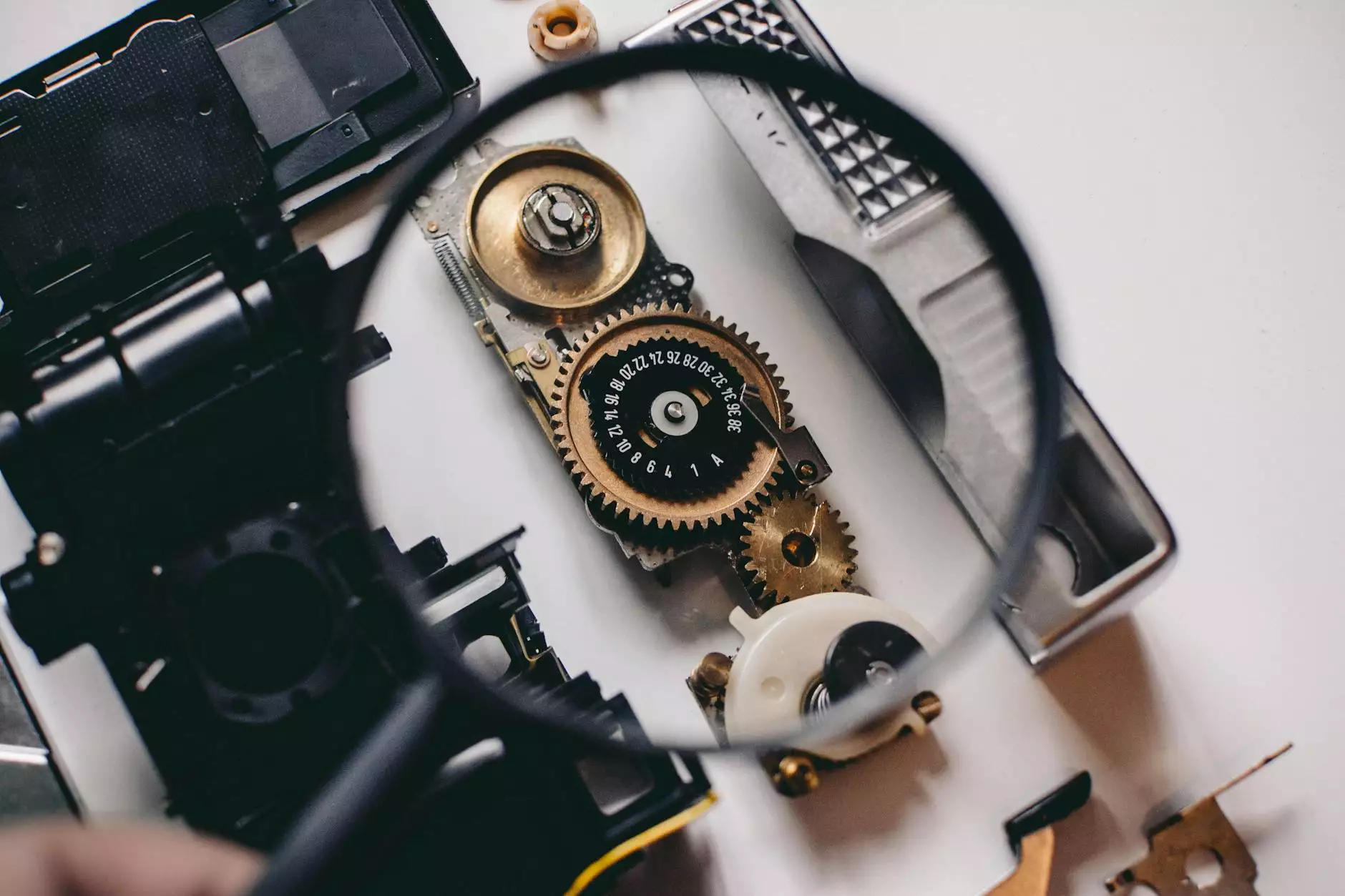

1. Precision and Accuracy

Accurate and precise manufacturing is a critical aspect in these industries. With OEM parts CNC machining, you can achieve unparalleled levels of precision and accuracy. CNC (Computer Numerical Control) machines are programmed to perform highly accurate movements, allowing for intricate and complex designs to be created with utmost precision. This level of precision ensures that your business can deliver superior quality products consistently, satisfying even the most demanding customers.

2. Enhanced Efficiency and Productivity

Time is money in the business world, and OEM parts CNC machining significantly improves productivity and efficiency. These machines are capable of performing multiple tasks simultaneously, streamlining the manufacturing process and reducing production time. By automating repetitive tasks, such as cutting, drilling, and milling, CNC machines allow your business to increase productivity while maintaining consistent quality.

3. Versatility in Material Options

Regardless of the industry you operate in, your business requires flexibility when it comes to material selection. OEM parts CNC machining provides the versatility you need by supporting a wide range of materials, including metals, plastics, composites, and more. Whether you need parts machined from stainless steel, aluminum, or brass, CNC machines can handle the task efficiently, ensuring that your business can cater to diverse customer requirements.

4. Cost-Effective Solution

Investing in OEM parts CNC machining is a cost-effective solution in the long run. While the initial investment may seem significant, the efficiency, accuracy, and productivity gains over time will offset the costs. By reducing operation downtime and minimizing material wastage, CNC machining helps your business save both time and money. Additionally, the consistent quality of CNC machined parts contributes to fewer product defects, reducing costs associated with rework or customer returns.

5. Rapid Prototyping and Iteration

Innovation is the driving force behind business growth and success. With OEM parts CNC machining, you can accelerate the prototyping and iteration process, bringing your ideas to life quickly. The ability to create accurate prototypes rapidly enables you to test and validate your designs, allowing for quicker adjustments and improvements. This agile approach to product development gives your business a competitive edge in the market, enabling you to deliver new and improved products faster.

6. Customization and Personalization

Today's consumers value customized and personalized products that cater to their unique needs and preferences. OEM parts CNC machining empowers your business to meet these demands effectively. With CNC machines, you can easily customize parts and components based on specific design requirements or customer requests. The flexibility in design and manufacturing offered by CNC machines ensures that your business can deliver tailored solutions, fostering customer satisfaction and loyalty.

7. Superior Surface Finish

The appearance and quality of your products play a significant role in customer perception. OEM parts CNC machining excels in delivering superior surface finishes, ensuring that your products not only meet functional requirements but also provide an aesthetically pleasing experience to customers. Whether it's a smooth, mirror-like finish or a textured surface, CNC machines can achieve the desired result, elevating the overall quality and appeal of your products.

Conclusion

In a competitive business landscape, embracing advanced manufacturing technologies such as OEM parts CNC machining is crucial for business growth and success. The precision, efficiency, versatility, and cost-effectiveness offered by CNC machines empower businesses in the Home Services, Contractors, and Building Supplies industries to deliver high-quality products, improve productivity, and meet customer demands effectively. By investing in OEM parts CNC machining, your business can gain a significant competitive advantage and position itself as an industry leader.

https://bccncmilling.com/oem-parts-cnc-machining/